A10VG: MS: P40-2: A10VG45: Max. Speed: 3550rpm Max.Pressure: 350 bars Cut off pressure: 300 bars Shell pressure: 5 bars Min.Pressure of return line : 25 bars Displacement of charge pump: 8.6cc FMS05: Max. Speed: 175rp...

A10VG:

MS:

P40-2:

| A10VG45: | |

| Max. Speed: | 3550rpm |

| Max.Pressure: | 350 bars |

| Cut off pressure: | 300 bars |

| Shell pressure: | 5 bars |

| Min.Pressure of return line : | 25 bars |

| Displacement of charge pump: | 8.6cc |

| FMS05: | |

| Max. Speed: | 175rpm |

| Max.Pressure: | 400 bars |

| Rated pressure: | 250 bars |

| Rated Torque: | 2570 N.m |

| Working Temperature : | -20 ℃~80℃ |

| Operating pressure Of brake: | 1.5Mpa~3Mpa |

| 02Z80: | |

| max flow: | 80L/min |

| max working pressure: | 180bar |

| Relief valve setting pressure: | 180bar |

| solenoid: | DC12V |

This customer is a professional manufacturer specializing in small loaders, a key player in the regional construction and agricultural machinery market. Small loaders are widely used in various scenarios such as urban construction, farmland improvement, warehouse handling, and road maintenance due to their flexibility, compact structure, and strong adaptability.

The customer has built a good reputation in the industry by focusing on the R&D and production of high-quality small loaders, with their products favored by small and medium-sized construction teams, farmers, and logistics enterprises. As the "heart" of small loaders, the hydraulic system directly determines the equipment's operational efficiency, stability, and service life.

Therefore, the customer has always adhered to strict standards in selecting hydraulic component suppliers, focusing on partners with advanced technology, reliable product quality, and comprehensive technical support capabilities.

Our company has established a stable cooperative relationship with this small loader manufacturer by virtue of our professional hydraulic system solutions.

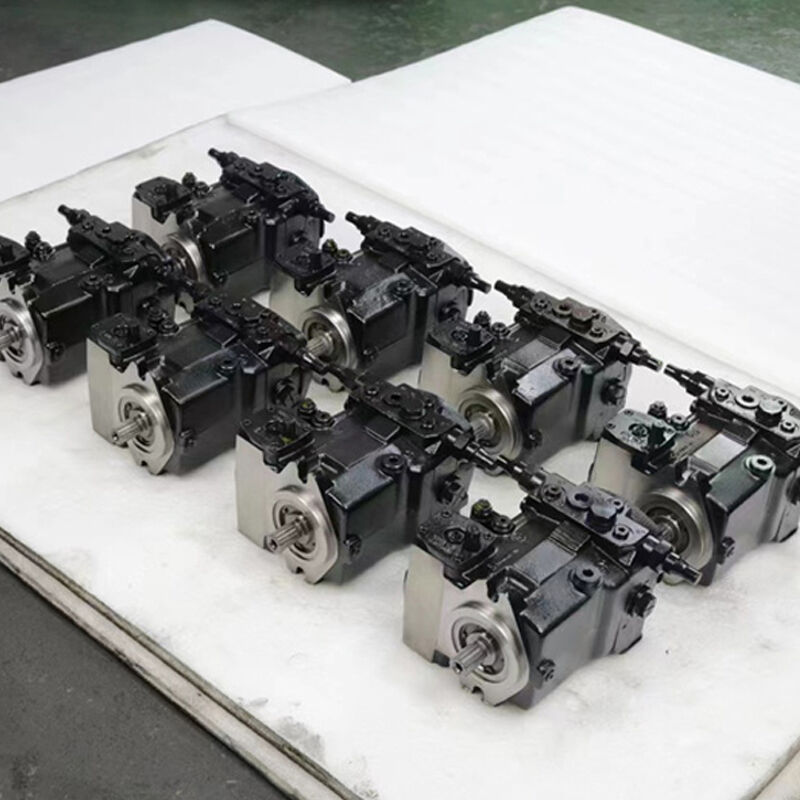

Initially, we customized a complete hydraulic system for their flagship small loader models, which consists of three core components: the A10VG plunger pump serves as the main pump, responsible for providing stable and continuous hydraulic power for the entire loader system; the FMS motor acts as the walking motor, ensuring the loader's smooth movement, flexible steering, and strong load-bearing capacity in various complex working environments; and we also provide both manual and electric control multi-way valves, which are used to control the lifting, tilting, and other key actions of the loader's working device. The perfect matching of these three components not only meets the basic operational needs of the small loaders but also enhances their overall performance and operational comfort.

Thanks to the reliable performance of our hydraulic system solutions, the customer's small loaders have achieved excellent market feedback, and our cooperation has also been further strengthened.