With the combination of piston motors and intelligent control algorithms, Prance Hydraulic can help change the pattern of hydraulic systems in future. This new way of doing things not only provides more efficient, reliable systems it also opens up possibility to the many ways hydraulic piston motor can help and be helped by a wide variety of industries.

Using Smart Control Algorithms to Utilize Piston Motors

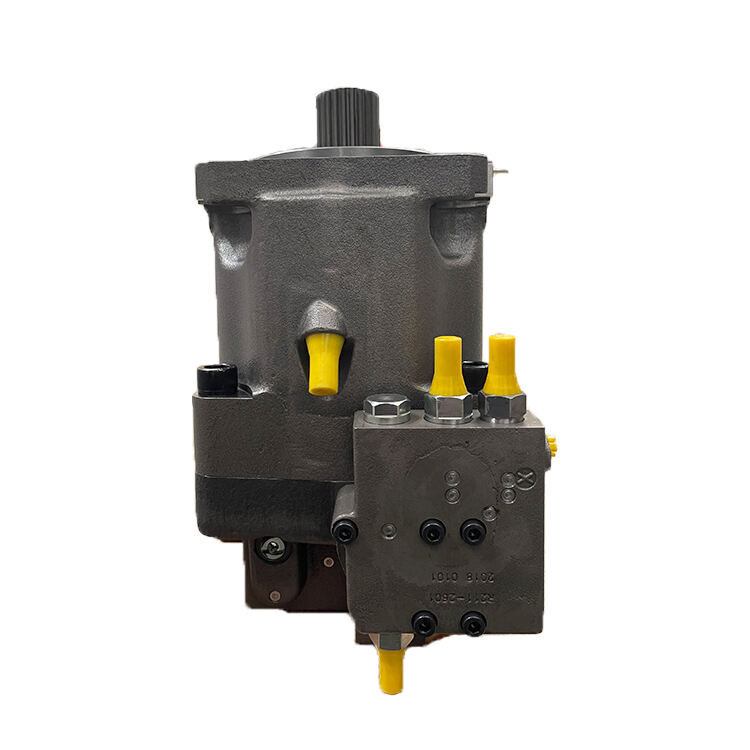

Prance Hydraulic is capable to improve the performance of hydraulic systems by combining highly efficient piston motors with intelligent control algorithms. The piston motors are of high power density and provide precise control across a broad speed range. When combined with intelligent control algorithm, the speed, torque and direction of these hydraulic piston pump motors can be adjusted on-the-fly to match various tasks' demands. This monitoring and control system contributes to energy savings, reduces wear on the hydraulic components for long life and minimal maintenance.

In addition, by use of piston motors and intelligent control software hydraulic systems become more accurate and have improved precision. The algorithms are capable of processing the data in real time and adapt adjustments based on the most current environment. The level of cleverness makes sure the hydraulic systems can react swiftly to load variations or fluctuating environmental conditions, and are always used in an optimal way. In general, the combination of piston motors and intelligent control algorithms provides more reliable, efficient fluid power systems suitable for broad range of industrial applications.

The New Technology For Hydraulic Systems

In the constantly changing world of hydraulic system technology, Prance Hydraulic prides themselves on being at the forefront of new trends. One of the emerging trends which is being adopted by radial hydraulic motor systems manufacturers across industries, is the use of IoT (Internet of Things) technology in hydraulic systems. If they tap into the network on their hydraulic components, then they have real-time status feedback, they can diagnose problems before something crashes and burns, and maybe even schedule maintenance proactively. This proactive approach to system maintenance results in higher performance and less down time, which ultimately benefits businesses by keeping their employees up and running.

Another trend on which Prance Hydraulic is betting is the emergence of environment friendly hydraulic fluids. As the industry evolves toward more sustainable and environmentally friendly products, manufacturers look for an alternative to classic hydraulic fluids that is biodegradable and non-hazardous. Prance Hydraulic uses these environmentally friendly fluids into their system, which results in not only improving the overall environmental impression but safety will always remain milestone for both users and environment as a whole,” according to the company.

We dedicate ourselves to the development of new hydraulic systems and improving all existing ones with an eye toward meeting the demands of the future market. Prance Hydraulic is one step ahead by integrating piston motors with intelligent control algorithms and developing state of art technology to be the world's reliable, efficient and sustainable hydraulic solution for many years.

Typical Usage Problems for Hydraulic Systems:

Hydraulic systems are something which is most popular in many industries as they can develop power through the use of fluids. But talking about the use of hydraulic systems there are some general problems we can face. One of the problems is leakage, which may be caused by seals and connections and wear on the system. This may result in fluid loss and loss of system efficiency. The other problem is a blown-up machine overheats, especially used it two or more days on end. Overheating can physically harm the hardware and shorten its life. Care and checking on hydraulic systems is necessary to avert these problems.

Intelligent Control Algorithms in Piston Machines:

To no longer have hydraulic systems be a challenge they need to future-proof with smart controllers and control algorithms connected to piston motors. Intelligent control algorithms use sensors and calculation of data to maximize the operation of the hydraulics. Such algorithms dynamically control fluid flow, pressure and other variables in order to optimize for efficiency and performance. Through loading logical control algorithm, the hydraulic systems can work more efficiently and can save energy and extend the service time between failures of their components. With this system, not only is more precise control and monitoring assured - key to greater system dependability and productivity.

Things to take into Account when Selecting Hydraulic Systems:

Selecting hydraulic systems for your applications When looking at choosing any of the available options below, consider which will best suit your specific requirements. The power of the system is also critical, it must be equal to the demands you have on your application. You should also think about the size, weight, how easy to install and maintain. Also don’t forget to take into account whether the system will work with your other pieces of equipment in your shop. By taking these considerations into account, you can select a hydraulic system that is dependable, performing and cost-efficient for your applications. At Prance Hydraulic, we provide various intelligent control algorithms to realize your operators future-proof and the highest efficiency.