4WRKE: 4WRZE: 4WREE: 4WRKE25: Max. Pressure: 350 bars Max.Flow: 870L Viscosity range: 20 to 380 mm2/s Hysteresis: ≤ 1% Response sensitivity: ≤ 0.5% 4WRZ32: Max. Pressure: 350 bars Max.Flow: 1600L Viscosity ran...

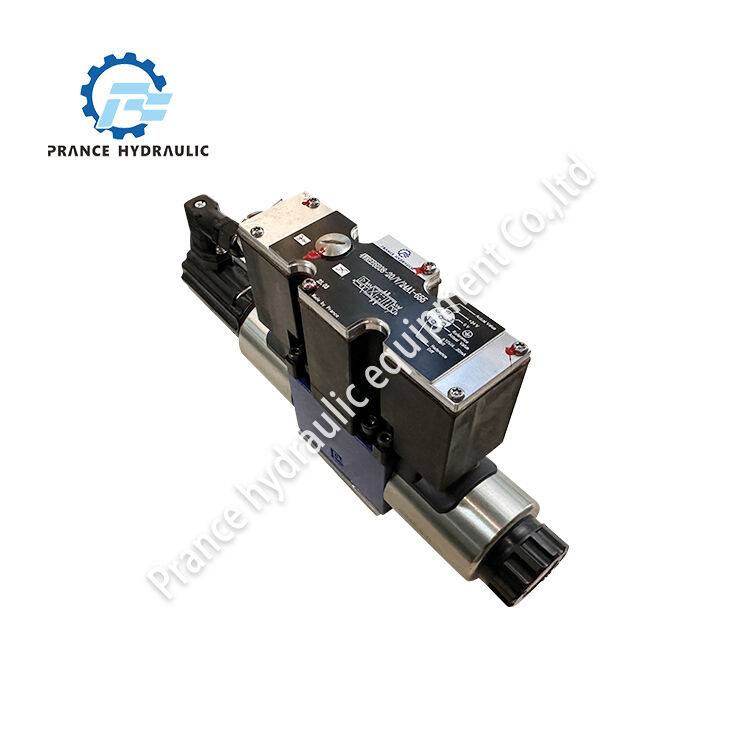

4WRKE:

4WRZE:

4WREE:

| 4WRKE25: | |

| Max. Pressure: | 350 bars |

| Max.Flow: | 870L |

| Viscosity range: | 20 to 380 mm2/s |

| Hysteresis: | ≤ 1% |

| Response sensitivity: | ≤ 0.5% |

| 4WRZ32: | |

| Max. Pressure: | 350 bars |

| Max.Flow: | 1600L |

| Viscosity range: | 20 to 380 mm2/s |

| Hysteresis: | ≤ 6% |

| Max.Current: | 2.5A |

| 4WREE10: | |

| Max. Pressure: | 315 bars |

| Max.Flow: | 180L |

| Viscosity range: | 20 to 380 mm2/s |

| Hysteresis: | ≤ 0.1% |

| Response sensitivity: | ≤ 0.05% |

4WREE

4WREE

4WREE

4WRKE

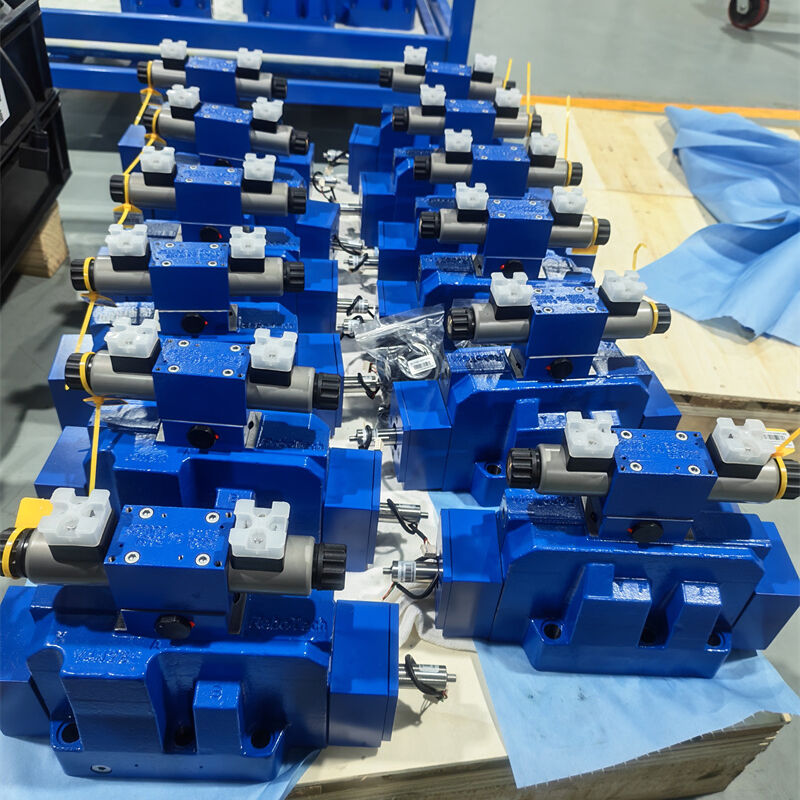

Our cooperative client is a well-known technical service company in Russia, which has long been deeply engaged in the steel mill supporting service field, providing professional technical support and equipment matching solutions for major steel enterprises in the country. With its profound industry accumulation and strict quality requirements, the client has extremely high standards for the performance, stability and technical compatibility of supporting equipment, which also lays a solid foundation for the in-depth cooperation between the two parties based on professional trust.

The cooperation between the two parties started in 2024, when the client needed to upgrade and transform the key production equipment of a cooperative steel mill. The core demand was to match high-performance proportional valves to ensure the precision control of the steel production process and improve production efficiency and product quality. After in-depth communication, our company recommended three types of proportional valves, namely 4WRKE25, 4WREE10 and 4WRZE32, according to the specific working conditions of the steel mill's equipment and the technical parameters put forward by the client, and finally determined to provide 10 units of each type.

With the joint efforts of both parties, after the proportional valves were delivered to the steel mill and installed, the on-site debugging work was carried out smoothly. Finally, all three types of proportional valves operated stably and efficiently on the equipment, accurately realizing the precision control of the production process, effectively improving the operation stability of the production line and the qualified rate of products. The client's technical personnel and the steel mill's relevant responsible persons highly recognized the performance of the proportional valves and our professional technical support services.