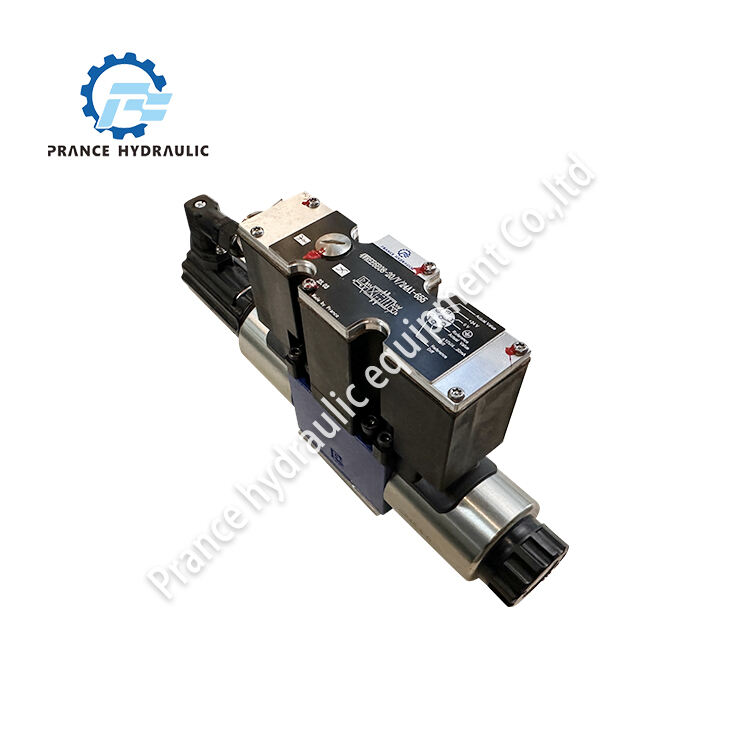

Proportional Valve 4WRE

Highlights and Innovations

1. Integrated Electronic Feedback

2.Robust Design and High Pressure Resistance

3.Improved Environmental Resilience

4. Advanced Industrial Interface

5.Fast and Precise Response

- Feature

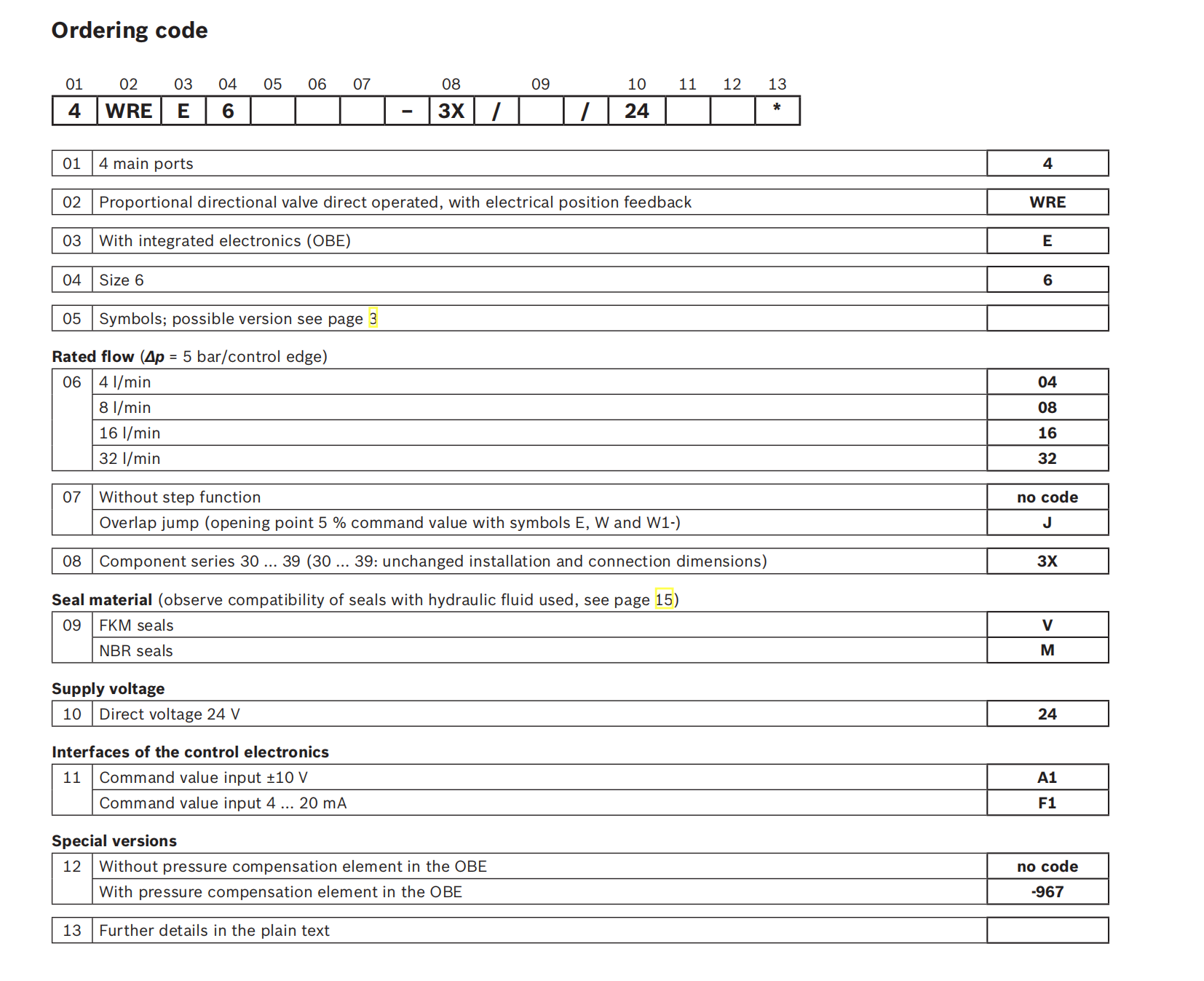

- Model code

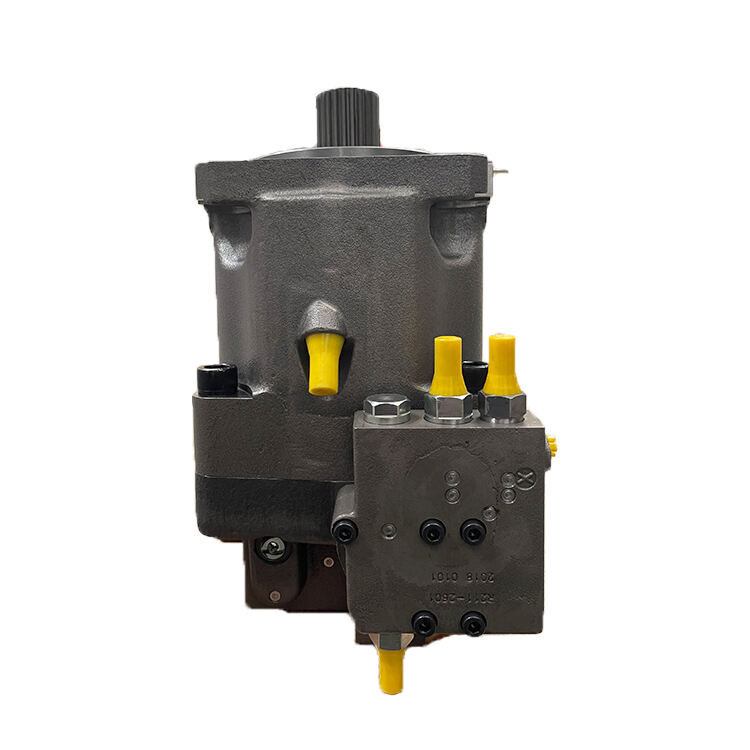

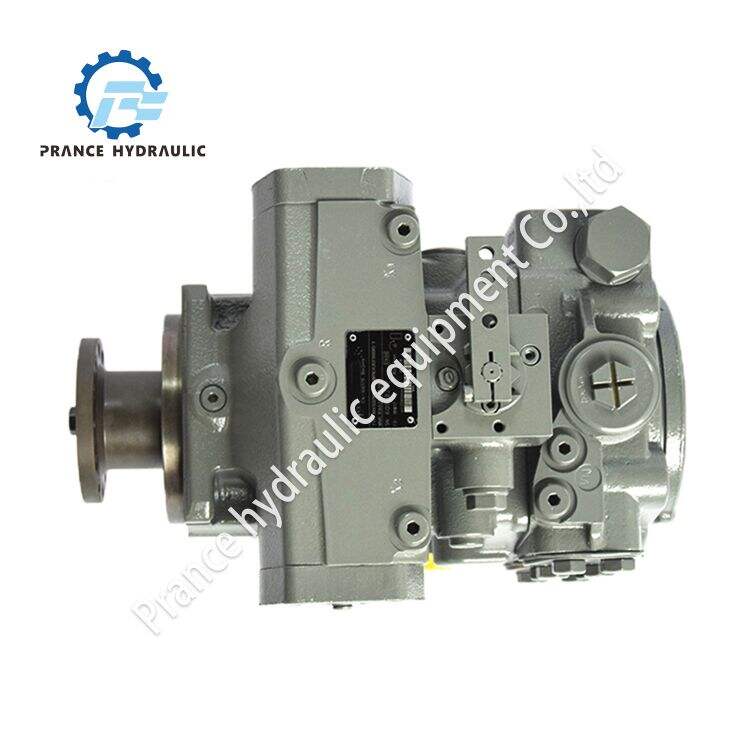

- Related Products

Feature:

1. Valve for controlling both direction and flow of a hydraulic fluid

2. For subplate mounting

3. Electrical position feedback

4. Spring centred control spool

5. Low pressure drop across the control lands

6. Both valve and electronic control from one supplier

7. Mounting pattern to DIN 24 340 form A, IS04401 and CETOP-RP121H

| Product | 4WRE |

| Application |

1.Bending Machines 2.Injection Molding Machines 3.Metallurgical Equipment 4.Wind Power Equipment 5.Oilfield Special Vehicles |

| Displacement/Size | -6, -10 |

| Control types | proportional solenoid control |

| Max pressure | 31.5 MPa |

| Max Speed | / |

| Max Flow | 180 L/min |

| Material | Carbon Steel |

| Guarantee Period | / |

| Customization or not | / |

| general | ||

| Weight ▶ Valve with two solenoids | kg | 2.6 |

| ▶ Valve with one solenoid | kg | 2.1 |

| Installation position | any,preferably horizontal | |

| Ambient temperaturerange | ℃ | -20...+60 |

| Storage temperature range with UV protection | ℃ | +5...+40 |

| Transport temperature | ℃ | -30...+80 |

| Maximum storage time | Years | 1(if the storage conditions are observed;refer to the operatinginstructions 07600-B) |

| Sine test according to DIN EN 60068-2-6 | 10...2000 Hz/maximum of 10g/10 cycles/3 axes | |

| Noise test according to DIN EN 60068-2-64 | 20...2000 Hz/10 gRMs/30g peak/30 min./3 axes | |

| Transport shock according to DIN EN 60068-2-27 | 15 g/11 ms/3 shocks/3 axes | |

| Shock according to DIN EN 60068-2-27 | 15 g/11 ms/1000 shocks/3 axes | |

| Maximum relative humidity (no condensation) | % | 95 |

| Maximum solenoid surface temperature | ℃ | 150(individual operation) |

| MTTFd value according to EN ISO 13849 | Years | 150(for further details see data sheet 08012) |

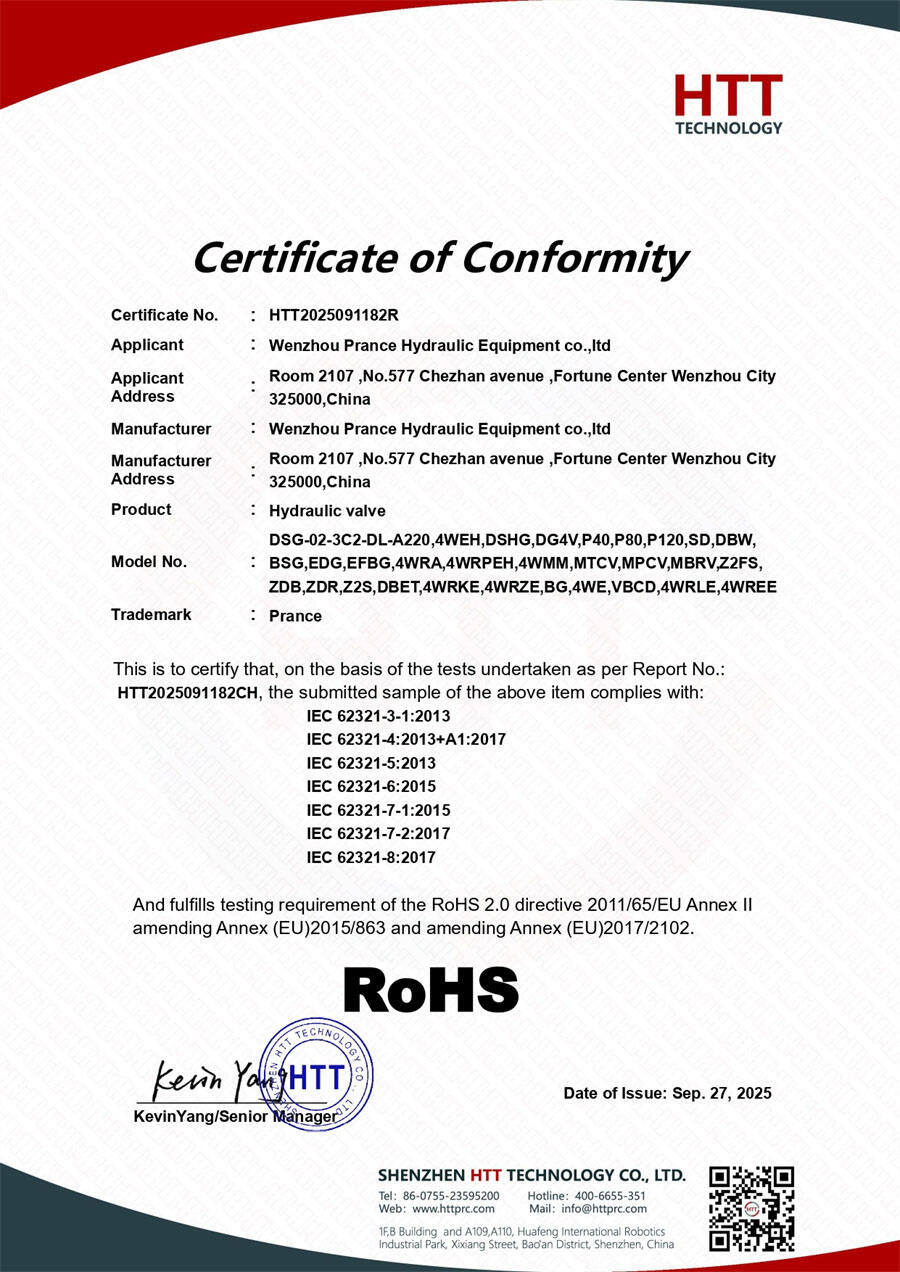

| Conformity | CE according to EMC directive 2014/30/EU,tested according | |

| to EN 61000-6-2 and EN 61000-6-3 | ||

| ▶ RoHS directive 2015/65/EU | ||

| ▶ REACH ordinance(EC)no.1907/2006 | ||

| Environmental compatibility ▶ Climate | Environmental audit according to EN 60068-2 | |