A6VM: A10VSO: A6VM Max.Pressure: 450bars Rated Pressure: 400 bars Minimum displacement: 40cc Volume efficiency : 97% Pilot pressure : 30 Bars Displacement : 80cc,107cc,160cc A10VO Max.Pressure: 320bars Rated Pressure : 28...

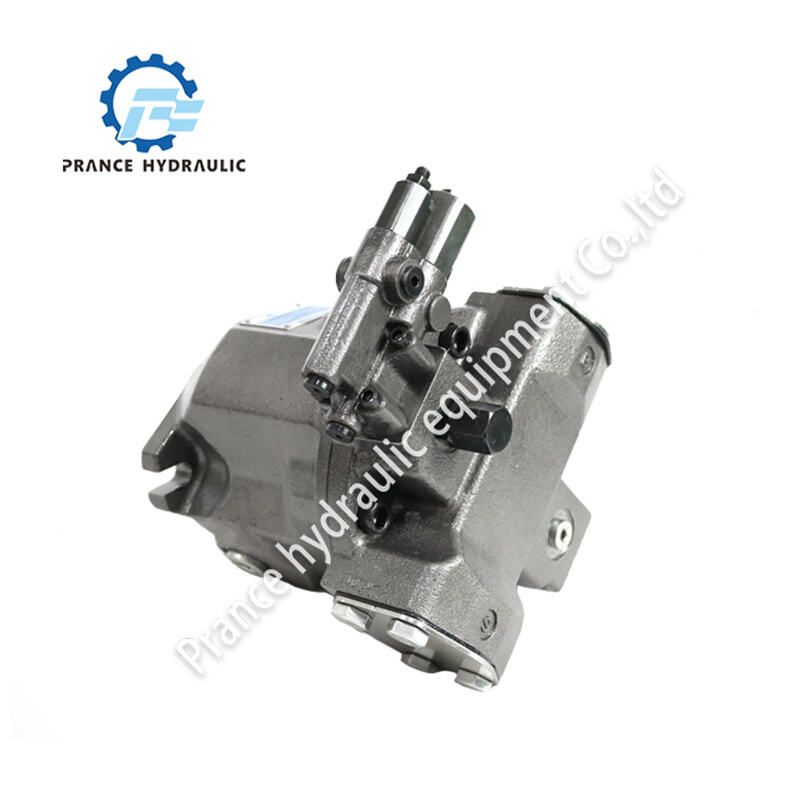

A6VM:

A10VSO:

| A6VM | |

| Max.Pressure: | 450bars |

| Rated Pressure: | 400 bars |

| Minimum displacement: | 40cc |

| Volume efficiency : | 97% |

| Pilot pressure : | 30 Bars |

| Displacement : | 80cc,107cc,160cc |

| A10VO | |

| Max.Pressure: | 320bars |

| Rated Pressure : | 280 bars |

| Volume efficiency : | 96% |

| Max.Speed : | 3900rpm |

| Displacement of pump: | 28cc,45cc,71cc,100cc |

Video of the customer's installation and usage:

A6VM

A6VM

A10VSO45-4L

A10VSO45-5L

This customer is a well-established drilling rig manufacturer based in India, holding a notable position in the local and regional mining and construction equipment markets. Specializing in the production of high-performance drilling rigs, the enterprise caters to diverse industry needs by manufacturing both surface drilling rigs and underground drilling rigs.

These plunger pumps cover a displacement range from 28cc to 100cc, a versatility that allows them to be integrated into different configurations based on specific operational requirements. To align with their unique usage needs, the customer connected these plunger pumps in series to form three-pump systems, a setup that enhances operational efficiency and meets the high-power demands of their drilling rigs. Reflecting the reliability of our products and the depth of our partnership, the customer’s annual purchase volume of the A10VO 31 series plunger pumps reaches 900 units.

In addition to the A10VO 31 series, the customer also procures our A6VM series motors, which complement the plunger pumps to form a complete hydraulic solution for their drilling rigs. The A6VM motors purchased by the customer cover a displacement range from 80cc to 160cc, and their annual purchase volume stands at 300 units. These motors and plunger pumps work in tandem to power the critical functions of the drilling rigs, ensuring smooth and consistent operation even under strenuous conditions.

As evidenced by the on-site video provided by the customer, the operating environment of their drilling equipment is extremely harsh. The rigs are often exposed to high levels of dust, intense vibrations, extreme temperature variations, and heavy-load operations—all of which pose significant challenges to the performance and longevity of hydraulic components. Despite these adverse conditions, our company’s complete set of solutions, comprising the plunger pumps and motors, has performed exceptionally well. To date, there have been no after-sales issues reported, a testament to the superior quality, durability, and reliability of our products. The customer has expressed high satisfaction with the performance of our plunger pumps and the overall stability of the hydraulic system, noting that our solutions have effectively supported the efficient operation of their drilling rigs and reduced operational downtime.