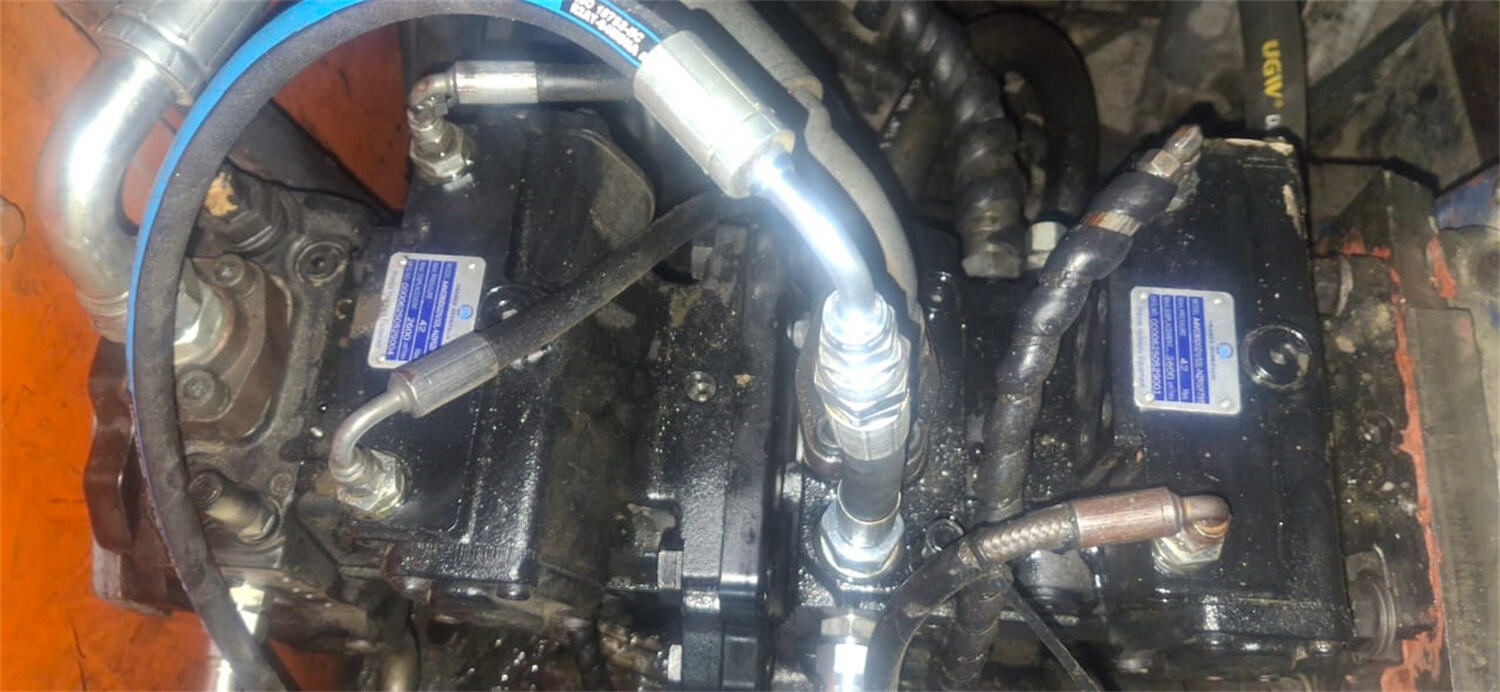

Video of client installation and usage: A4VG90DG+A4VGDG: Max. Speed: 3800rpm Max.Pressure: 450 bars Cut off pressure: 380 bars Shell pressure: 5 bars Max. Suction pressure: 5 bars Displacement of charge pump: 18cc PbkCEb P...

Video of client installation and usage:

| A4VG90DG+A4VGDG: | |

| Max. Speed: | 3800rpm |

| Max.Pressure: | 450 bars |

| Cut off pressure: | 380 bars |

| Shell pressure: | 5 bars |

| Max. Suction pressure: | 5 bars |

| Displacement of charge pump: | 18cc |

PbkCEb

POJpaE

This client is a professional technical service company based in South Africa, specializing in providing equipment maintenance, repair, and replacement services for the local mining and drilling industry. As a trusted partner for numerous industrial enterprises in South Africa, the company has built a solid reputation for its efficient service response and professional technical capabilities.

In the mining-dominated South African market, drilling rigs are critical equipment for mineral exploration and extraction, and their stable operation directly affects the production efficiency and safety of mining enterprises. Therefore, the technical service company has always been rigorous in selecting cooperative partners for equipment and maintenance services, focusing on suppliers with rich industry experience, high-quality products, and reliable technical support.

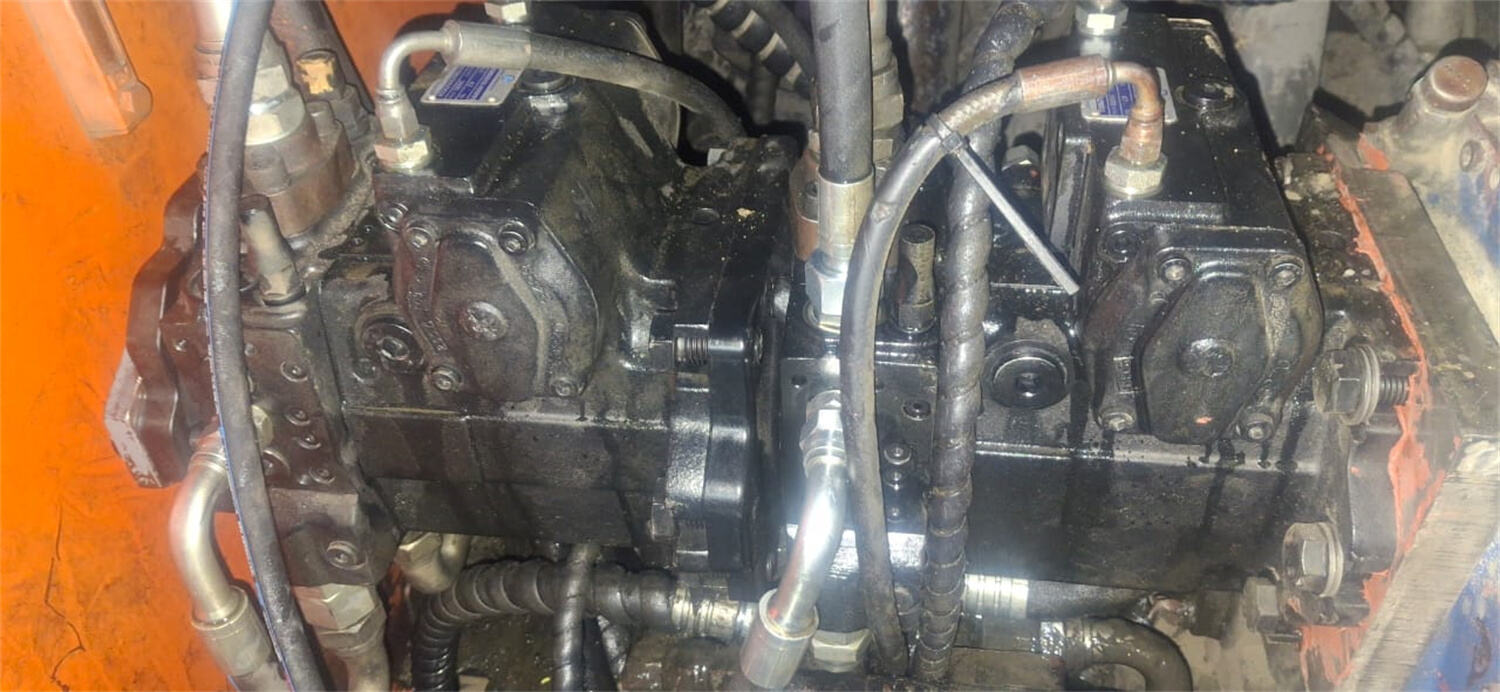

Our company officially established business cooperation with this South African technical service company in 2024, marking our entry into the local drilling rig maintenance and equipment replacement market. The initial cooperation originated from a key project: the technical service company entrusted us to assist in maintaining drilling rig equipment for one of its local end users—a well-known mining enterprise engaged in large-scale mineral exploration and mining operations.

At that time, the end user’s drilling rigs had been in long-term high-intensity operation, leading to wear and tear of some core components, which seriously affected the normal progress of mining work. Faced with the urgent needs of the end user, our company quickly responded by dispatching a professional technical team with rich experience in drilling rig maintenance to the site.

Our technical team first conducted a comprehensive inspection and diagnosis of the end user’s drilling rigs, accurately identifying the faulty components and formulating a detailed replacement and maintenance plan.